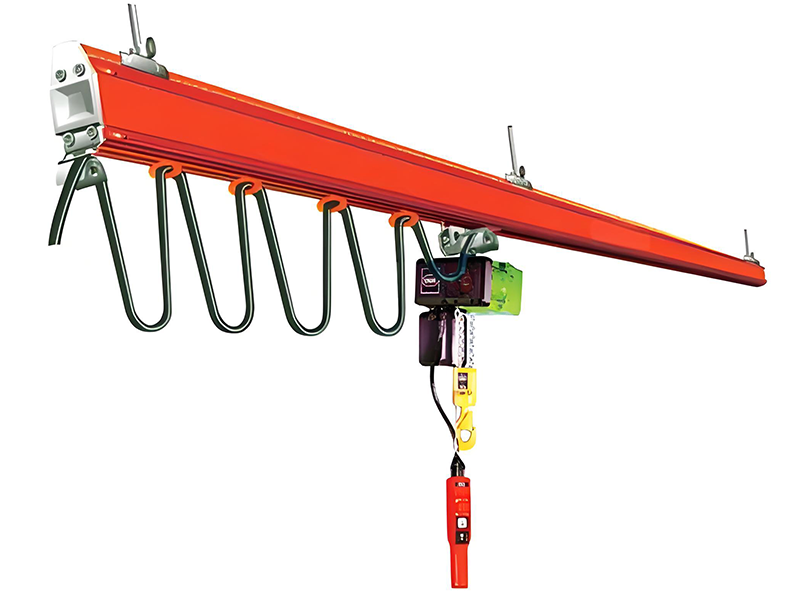

KC rigid single girder/double girder combined crane

Classification:

Product Information

KC rigid combination crane belongs to light and small cranes, which is composed of a series of modular, standardized design parts, including bracket, suspension trolley, motor, travel rail, guide rail and electric hoist. Mainly used to solve the problem of small and medium weight material handling high frequency. Its maximum lifting capacity can be up to 3200 Kg. Because of its simple structure, lightweight and flexible, KC cranes are widely used in a variety of light lifting occasions.

Design Advantages of KC Rigid Combination Cranes

Humanization

Ergonomic design and unique rail design, the rail adopts the downward opening C-type closed rail, the internal friction of the rail is smaller, less noise.

Economical

Key components such as rails and trolleys are self-manufactured and guaranteed by special tooling for durability.

KC Rigid Combination Crane Design AdvantagesLow maintenance costs and longer warranties in the industry (including trolley and wheels)

No welding, easy to install and dismantle

Self-contained structure reduces the use of steel for lower costs

Flexibility

Large spacing of lifting points, can be designed according to the actual situation, and at the same time to ensure sufficient safety and practicality

Carrier wheel bearing adopts domestic first-class brand, 1:100 labor-saving design, more convenient and efficient manual operation

Higher standard, more safety

All combination cranes have 40% safety design factor (considering 15% hoist weight and 25% impact load)

Finite element analysis is used for strength and stiffness checking, rail design vertical stiffness L/500, main beam design vertical stiffness L/750-L/1000 (crane design standard)

Side bending within the length of 6 meters does not exceed ±2mm.

The rail and main girder are pre-installed with corresponding upper arch according to different spans.

Multiple safety protection between rail and main beam, main beam and hoist.

Product Picture

Application Case

Online consultation

Please enter your contact information and we will contact you as soon as possible!

Related Products