Intelligent Lifter

Classification:

Key words:

Product Information

Intelligent hoist is a material handling equipment that combines advanced sensor technology, intelligent control system and planetary gear reducer, aiming to improve the efficiency and accuracy of material handling in industrial production. It usually consists of servo motors, servo drives, load cells, limit switches, etc., and is controlled by a processor. It is ergonomically designed for easy operation, high accuracy, controllable speed, safety and reliability. It provides a real choice for enterprises to significantly improve production efficiency and reduce labor costs.

The features of the intelligent hoist include:

Precise control: through advanced sensors and control systems, it realizes precise control of the lifting equipment to ensure accuracy and stability in the lifting process.

Load balance: real-time sensing of the weight of the goods, automatically adjusting the lifting force to maintain the balance of the goods in the hanging process.

Flexible and maneuverable: The design takes into account the diversity of the working environment, able to operate in a narrow space and adapt to the needs of different working environments and scenarios.

Multiple safety protection mechanisms: including overload protection, limit protection, emergency stop protection, etc., to ensure the safe operation of the equipment under various working conditions.

Intelligent hoist is widely used in machinery manufacturing, automobile assembly, electronic manufacturing, logistics and warehousing industries for handling goods of various shapes and weights, such as plates, tubes, boxes, parts and components.

The main technical parameters of intelligent hoists include lifting capacity, lifting height, lifting speed, working voltage, power and so on. Its advantages include:

High-speed handling: with the function of “infinitely variable speed”, the speed can be adjusted accurately according to the requirements of different working conditions to improve working efficiency.

Precise positioning: through the “suspension mode” function, it can realize highly accurate operation, which is suitable for precision machining and assembly.

Intelligent control: Adopting advanced control system and sensing technology, real-time monitoring of operating commands and equipment running status to ensure the stability and reliability of equipment operation.

Safety: Equipped with fault diagnosis function, photoelectric sensing device and weight sensing function to prevent misoperation and overloading.

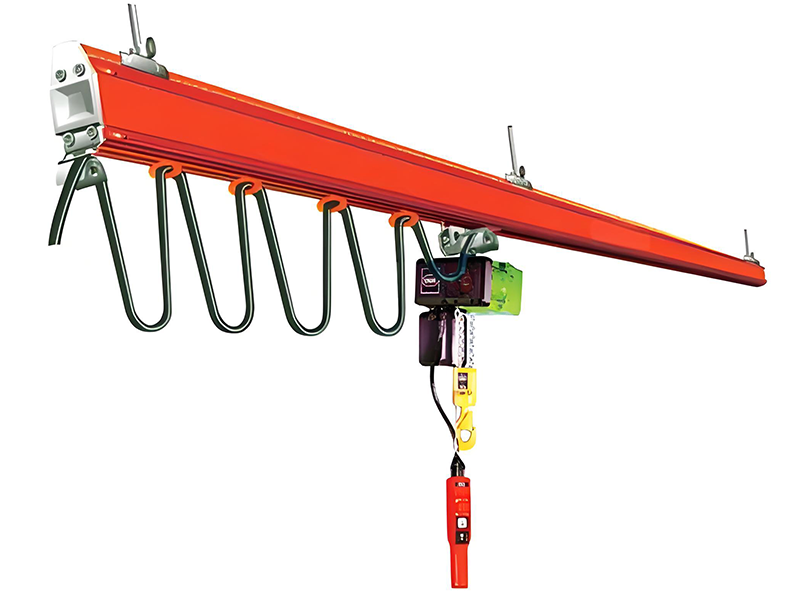

Product Picture

Application Case

Online consultation

Please enter your contact information and we will contact you as soon as possible!

Related Products